The Cost Implication Of Molded Pulp Over Others

US interest for molded pulp (or shaped fiber) packaging is estimated to increase 6.1% yearly to $1.3 billion every 2024, as per another Freedonia Group examination. The request is relied upon to move at a powerful speed because of the formed mash’s ecological benefits, explicitly its recyclability, biodegradability, and capacity to be treated the soil in modern offices. Other key components supporting solid deals development include growing acknowledgment of formed mash’s presentation benefits, including brilliant padding, propping, and impeding the improvement of formed fiber items that are more serious with plastic choices as far as cost, execution, and feel reaction against single-utilize plastic items fabricated from extended polystyrene (EPS) froth, just as restrictions on certain EPS foodservice items in a developing number of urban areas.

Advantages

Molded pulp Lowers Costs by 70%

Expenses related to the cost of a thing incorporates transportation, warehousing, work, and plan. We set aside our client’s cash and assets consistently in every one of these classes. Molded pulp can lessen costs by as much as 70% when contrasted with other packaging materials. Since our molded pulp is produced using 100% reused paper (generally post-mechanical), our expense for crude materials has been truly steady for quite a long time. We give these investment funds to you.

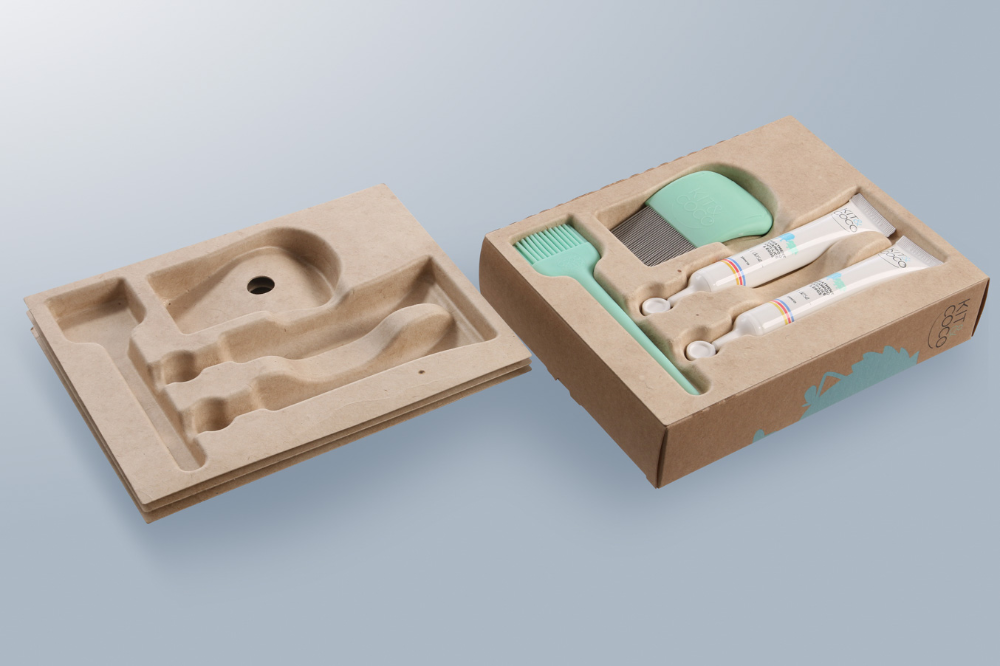

Molded Pulp Saves Valuable Space

molded pulp packaging to home and stack together. That takes into consideration a more noteworthy amount on every single bed empowering our clients to send more per load. The expense reserve funds for certain parts can deliver half less delivery volume, also the distribution center space needed for capacity on your industrial facility floor.

Molded Pulp Saves Valuable Time

Time is cash, and shaped pulp packaging saves time at each progression all the while. Costly work costs for get-togethers are wiped out. Shipments are less successive, which saves transportation time. Giving fewer requests and solicitations likewise prompts a decrease in authoritative time. Shaped mash is prepared to utilize when it shows up at the purpose in packaging.

Offers Protection and Cushioning

Probably the best thoughts have been around for some time. Molded pulp has given delicate insurance to eggs for more than 100 years. It has displayed predominant execution in vibration tests and gives unequaled insurance against the harmful impacts of vibration and shock. Our custom mash items have passed thorough testing and have met the necessities set by UPS, FedEx, and ISTA. Less breakage rises to fewer migraines.